The Business Need

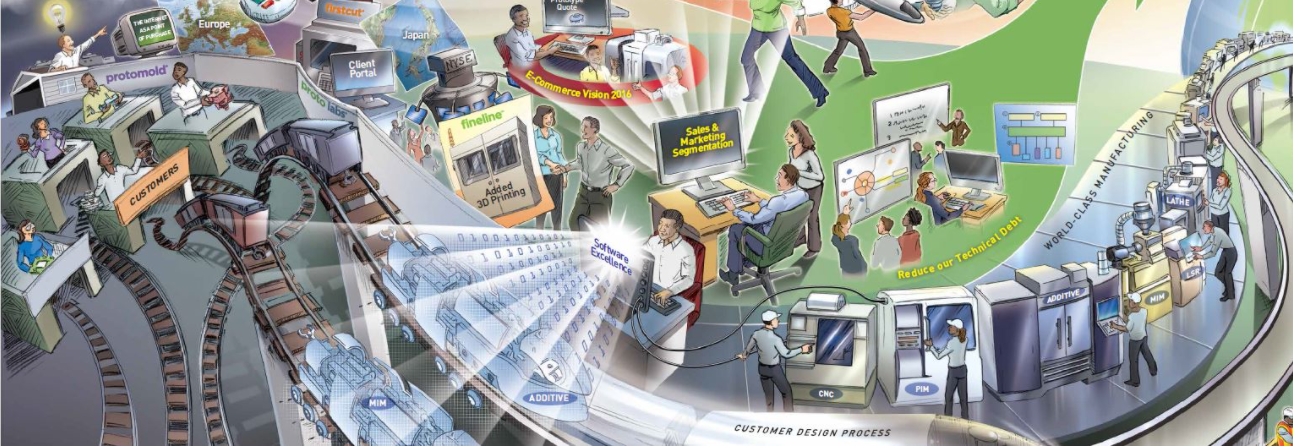

PPG Fiber Glass, the world’s leading coatings, specialty products, and services company, was evolving from a mass production system to a lean-based customer pull manufacturing system to enhance organizational adaptability, better serve the changing needs of the customer base, and reduce the working capital or cash required to operate the business. In the past, the organization would have determined what was changing within each of the functions and trained only those employees on the tactics of what they needed to do differently. This time, they used a different approach. PPG wanted all employees to see the big picture of the business from the leaders’ point of view.

The Solution

As many companies do, PPG leadership keeps score with metrics such as earnings per share, return on capital, and free cash flow. But often, when these words are “translated” for people, they hear something different. They hear things like “reduce inventory,” “pay suppliers slower,” or “manage TAKT time.” Leaders often inundate employees with tactics, but fail to provide them with the big picture of the business from the leaders’ point of view.

Partnering with Root, PPG told the story of the business to each of their employees, helping them to understand the importance of cash flow, the key drivers of cash flow, and how their individual behaviors needed to change in order for the organization to optimize their cash position.

It was vital for plant-level employees to understand that a shift from mass production to lean didn’t necessarily mean head-count reductions. In fact, certain plants were able to add head-count because they built a core competency in responding to the changing needs of the customer – something they could have never achieved with mass production.

The experience also demonstrated that effective cash management wasn’t just the job of the finance department. Effective cash management is the job all employees from sales to purchasing – for example, helping the sales and customer service organization understand the value of cash management and how it linked with a lean customer pull manufacturing model. Understanding the opportunity and how the entire business model fit together allowed employees to better sell the benefits to their customers.

Results

PPG has successfully moved to a customer pull manufacturing planning model, and their customers now understand that their orders drive the production scheduling. The Root Learning Map® sessions helped all functions of the business understand the importance of our new model and how it could enable PPG to reduce inventory while at the same time improving customer satisfaction and order fulfillment.

As a result of our focus on cash flow, we’ve been able to manage the downturn better than many of our competitors. For instance, as a result of the Fiber Glass business unit focus on cash flow, we increased our inventory turns by 28% in 2008. The Fiber Glass business unit was also a contributor to PPG’s fourth quarter of 2008 cash flow improvements when the company increased its cash position from $526 million to $1.02 billion.

Disruptive Methods Applied